Marju has been working in the mill laboratory for almost 34 years

What feeds the happiness of a Mills worker? - A job that feels like a second home. Kind colleagues and a manager who is a nice person. A family company that values and trusts you, gives you responsibility and is flexible," says Marju Aho, who has worked at Helsinki Mills’ laboratory for 34 years.

– I remember the exact date: I started at Helsinki Mills in Sörnäinen on 27 August 1991. I had left my shift work at the Paasivaara factory to take my first maternity leave when I took out the phone book and started calling around for lab technician jobs. When I called Elvi Ikäheimonen, a lab technician at Helsinki Mills, she told me to contact her again in the autumn. Elvi then tipped off her supervisor Risto Tukiainen about me, and after an interview with him, I got the job.

– A smaller, privately owned family business and competitive salary tipped the scales when the alternative was a veterinary laboratory.

– For me, a family business is all about continuity. It is very important that we employees know that operations will continue, Marju reflects.

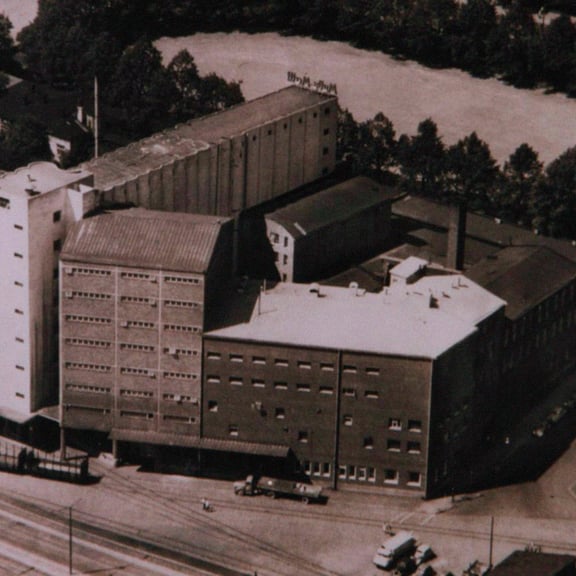

For the young lab technician, the old mill in Sörnäinen, Helsinki was a scary place at first.

– When you entered the laboratory on the 8th floor, it was like entering a museum," Marju recalls.

As Elvi's apprentice and Niklas's coworker

To the young lab technician, the ancient Sörnäinen mill seemed like a scary place at first. The big, dark, old building had many floors and a lot of decommissioned machinery. Compared to the equipment donated by the Käpylä Laboratory School, the equipment in the mill's huge laboratory was even older - except for a new falling number machine.

– It was like entering a museum, Marju recalls.

The welcome and introduction to the sector by Miss Elvi was even friendlier.

– The cereal side was completely new to me: I had never seen cereal grains except in fields. I had never held grains in my hands.

However, her interest was piqued, and the kind-hearted Elvi gave Marju the training she needed to work in the laboratory. Soon after, Elvi and Risto encouraged Marju to complete the then mandatory Bread and Feed Grain Researcher qualification. The three-page exam required mastery of the 1975 Grain Trade Guide.

– I went to do the required demonstration at the state grain warehouse.

Before retiring, Elvi and Marju moved the laboratory from Sörnäinen to the new mill in Järvenpää, where the grain reception and the laboratory are in the same building. In a master-apprentice style, Marju has introduced new mill workers to the mill's laboratory operations and evolving technology over the years.

– The sons of the owner family have also been learning on the job during their introduction to working life periods. For six months, I worked with the current CEO, Niklas Kumlin, on a daily basis, as he familiarised himself with the various tasks of the mill in the grain reception and laboratory.

Varying weeks, like-minded team

The mill laboratory of the 2020s is very different from the one of just over 30 years ago. Mechanical devices, pens and paper have given way to information technology and computers.

– The amount of work has multiplied since I started. We are now more precise in some matters. On the other hand, before, parallel samples were always taken from each batch, meaning that they were tested twice. Now the IFS certificate defines the approach: only what is marked as tested is considered tested.

In Sörnäinen, the samples to be tested were transferred from the grain reception on the ground floor to the 8th floor laboratory via a pipe. An indicator light indicated that a batch has arrived. Now, grain recipient Jukka Huurinainen is part of a three-person team with laboratory technician Elina Villinki and Marju.

– Elina and I share a table, and we work on different sides of it. Every week we change sides. During grain week I analyse the incoming wheat and rye, during flour week my hands are literally in the dough. We use a farinograph to analyse how much water the flour absorbs, and an extensograph to measure the durability of the dough. We conduct analyses for our own test bakery when our product developers have a quality baking day, says Marju, who values variety in her work and having like-minded colleagues with whom she can get things done.

On the grain side, work progresses according to the incoming loads: within half an hour or so, samples are already being processed, and analyses are completed within 15 minutes.

– When 50,000 tonnes of wheat or rye arrive at the mill, about ten kilos come to us for analysis. Approximately 300 grams are needed for the determination of the falling number, about 100 grams for the examination of level of gluten.

– On the cereal grain side, you don't know in the morning how many grain loads will arrive during the day. On the flour side, you can decide in the morning in which order you want to work. More flour samples are coming in throughout the day, says Marju.

Team at work. Marju Aho examines the dough formation time with a farinograph, with laboratory technician Elina Villinki and grain receiver Jukka Huurinainen in the background.

Skate skiing, tour skating, roller-skating, cycling and going to the gym are all part of Marju's leisure activities.

– I must have time for exercising several times a week.

”Omani ja yrityksen arvot kohtaavat”

"My values and the values of the company meet"

The 57-year-old mother of three and grandmother of five lives in Nurmijärvi, Klaukkala village. During her half-hour commute, Marju talks to her mother on the phone almost every day. She meets her offspring weekly and her large circle of friends regularly.

– Family and friends bring joy and balance to life. Exercising is my passion: I must have time for it several times a week. I got hooked on the gym 2.5 years ago.

Marju has always liked sports that are a bit more fast-paced. She has played tennis for 40 years, but now her knee has forced her to take a break from the beloved hobby she shares with her daughter. Last winter, Marju got into tour skating. Cycling, roller-skating and skate skiing are also among her favourite sports.

This social and energetic woman who also loves to read still finds time to pop into her home kitchen.

– When the children were at home, we baked rolls or sweet buns every weekend. Homemade rolls are still always available. My boyfriend likes it too. The number one product for rolls is Myllärin Organic Multigrain Bun Flour, Marju advices.

Let's return from home at Nurmijärvi to the mill in Järvenpää. What has kept Marju happy for decades at Helsinki Mills?

The workplace feels like a second home. The staff are relaxed and friendly. The employer cares about us. We have excellent benefits, from dentists to massage therapists, Marju explains with an example.

– My values and the values of the company meet. I take responsibility for my own actions, and I always try to get a lot done. I value freedom and flexibility. People here trust that we are responsible, that we know what we are doing and how to do it. No one tells you what to do; you can decide for yourself how to carry out your work tasks. The manager is a nice person who does not dictate things. We are on the same wavelength: we can discuss and disagree.

There are many farmers in Marju's home village, and Myllärin 2.0 wheat is also smartly grown in Nurmijärvi.

– I want to be confident that security of supply will be maintained and that farmers will be able to continue. For me, a family business is all about continuity. And it is very important that we are also told that the operations will continue, Marju Aho notes with satisfaction.

The workplace feels like a second home. The staff are relaxed and friendly. The employer cares about us.

– At home, there are always homemade rolls on offer. The number one product for rolls is Myllärin Organic Multigrain Bun Flour, which is just getting a new package, Marju says.

Marju and Elina ensure product quality, safety, and functionality

The laboratory at the Järvenpää mill conducts research into a wide range of issues related to grains and flours in order to guarantee the quality and safety of Myllärin wheat and rye products.

1. QUALITY CONTROL OF RAW MATERIALS

- The protein content affects the baking properties, i.e. how the dough absorbs water and withstands kneading. For example, the protein content of baking wheat flour is 12.5-14.5%.

- Moisture content affects the success of storage and grinding. The maximum moisture content of the cereals received must not exceed 14,0 %.

- Bushel weight describes the fullness and quality of the grain.

- Falling number measures enzyme activity. A low falling number indicates premature germination and can impair bread-making properties: the dough does not rise, and the inside of the bread remains doughy. For example, coarse wheat flour made for baking has a falling number of 280-350, while coarse rye flour has a falling number of 110-150.

2. CHARACTERISTICS OF FLOUR

- Viscosity measurements with a farinograph and extensograph are used to determine the behaviour of the dough during kneading and baking.

- The wet gluten content indicates the amount of gluten, the protein that forms gluten in wheat.

- The water binding indicates the achievable dough result. Water binding is influenced by factors such as ash content, flour moisture, protein content, and the amount of starch broken down during milling.

- The mixing and stretching properties of the dough tell you how well the flour will stand up to kneading and what the final bread will be like - the shape, texture, and ease of baking are all made apparent by values measured in the laboratory.

- The ash content tells you how close to the kernel the flour is. The more grain husk layers there are in the flour, the higher its ash content. For example, special wheat flour has a maximum ash content of 0,58 %.

- The degree of coarseness of the flour affects the structure of the dough and the mouthfeel of the final product.

3. ENSURING HYGIENE AND SAFETY

- Microbiological analyses are performed on products and the production environment to check for molds, yeasts, pathogenic bacteria, pesticide residues, heavy metals, toxins, and allergens, among other things.

– I had never held grains in my hands before I started at the Sörnäinen mill in August 1991," says Marju. However, Miss Elvi Ikäheimonen trained Marju so well that her career at the Helsinki Mills laboratory has continued for almost 34 years.

Järvenpää invested in sifter cabinets

– More screening area means we can produce higher quality flour more efficiently. As yields increase, production capacities also increase, says Martti Loikkanen, Plant Manager at the Järvenpää production plant when he talks about the investment of just under one million euros. Read more

Miller-Villes learn from Switzerland

Although the mill’s core principles remain unchanged, milling operations continue to evolve with new equipment. At Helsinki Mills, learning and development take place as part of everyday work, but training also plays an important role in deepening expertise. We have several professionals who take responsibility for flour quality. Read more